TrendMiner, a Software AG company

Update solution on February 28, 2020

TrendMiner is a self-service analytics solution designed for domain experts within the process manufacturing space, providing trend analysis and root cause identification in the case of production issues, and predictive capabilities. It addresses both batch-based process manufacturing, as in the chemical and pharmaceutical sectors, and continuous processes as in oil refining.

Customer Quotes

“A TrendMiner soft alarm on impurity concentration gives direct insight in product quality.

As a result, truck loading can start earlier, lead time is shorter and the probability of rejection due to off-spec conditions has significantly decreased.”

European Chemical Company

“TrendMiner is a user-friendly self-service analytics tool that provides us with tremendous time savings and delivers better quality results than data models. Process Engineers, Technologists, Run Engineers or Operators… Thanks to TrendMiner, they can unlock the power of the industrial data for their day-to-day questions.”

TOTAL Refining and Chemicals

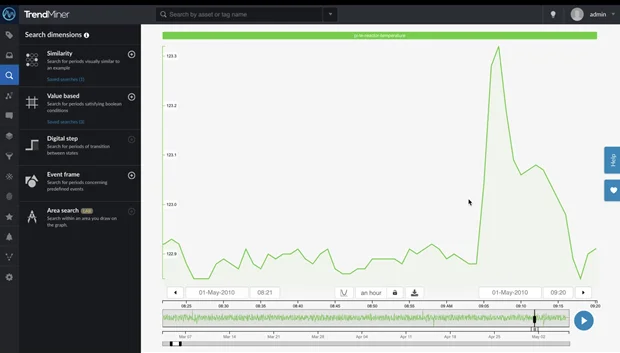

TrendMiner is used to analyse time-series data (Figure 1 provides a typical illustration) that has been collected from perhaps millions of sensors spread across a process manufacturing site. There are three principle components within the product: TrendHub, ContextHub and DashHub. The first is used for actual trend and root cause analysis, but also allows you to monitor good process behaviour, providing early warnings. It may also be used with soft sensors. The second hub is used to capture automatically generated or manually entered operational events and is also used to augment the collected data with third party contextual information, such as SAP PM, LIMS or ERP systems. The third hub is used to make analytics-driven visualisations for creating personal production cockpits. However, rather than continue to describe each of these separately it will be more useful to describe how the solution works in practice.

Figure 01

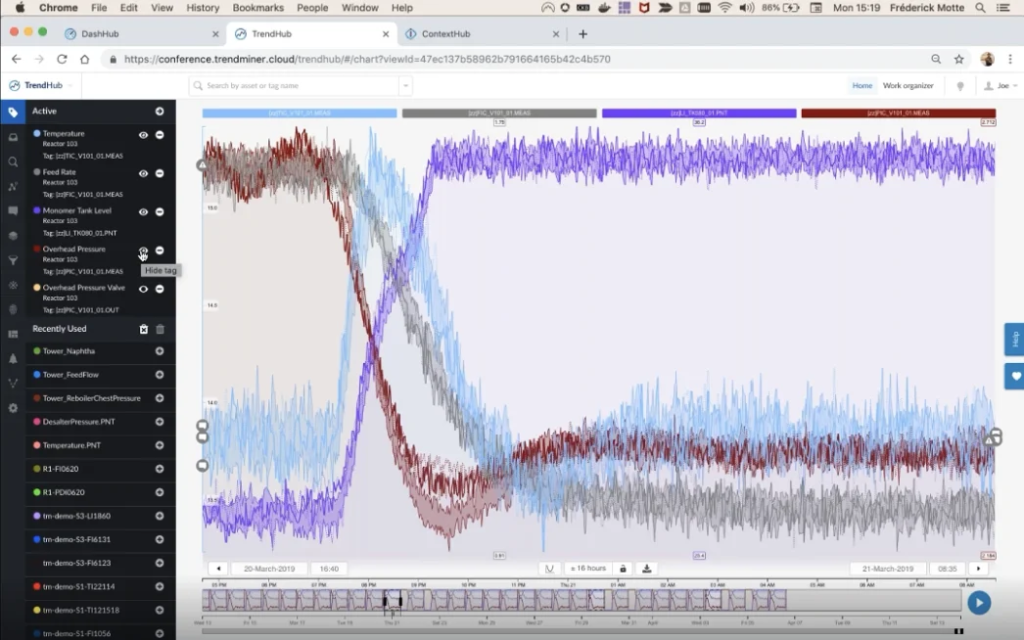

For example, you are in a batch processing environment and some of your batches have been identified as sub-standard. You want to determine what has gone wrong. You start by identifying a baseline (Software AG calls it a fingerprint) of what a normal batch process should look like. You do this by taking the time-based profile of multiple successful batches and overlaying them on one another, filtering by key performance indicator (KPI). This is a very simple and more or less automated process. You then compare – again in an automated fashion – the anomalous results with the ones you expect, with the results presented to you visually. Figure 2 represents the results of such an exploration where the grey, blue and purple fingerprints, each representing a different KPI, do not show any significant differences, whereas the deep red fingerprint does show a significant divergence, suggesting that there is a problem with whatever is represented by that fingerprint.

Figure 02

Reverting to a more technical description of TrendMiner, notable additional features include both a recommendation engine and (patented) pattern recognition. In the case of the former, the engine – enabled by machine learning – will make suggestions about what might be the cause of a problem, which will be particularly useful when causes might be non-obvious. As far as the latter is concerned, the software can recognise recurring patterns and use these to support predictive maintenance and similar functions. This is further supported by the ability to raise alerts or trouble tickets in the event that a particular pattern, or combination of patterns, or the absence thereof, is identified as having (not) occurred. The product also includes a similarity search capability – searching for similar patterns – whereby you define how precise you want this similarity to be: 95%, 99% or whatever.

Some relevant geo-spatial capabilities are supported by TrendMiner through the use of APIs or via Software AG’s integration capabilities. For example, you can create a map of your assets that can relate directly to asset related sensor data as a part of analysing its performance. In this way, the geo-spatial structure of your plant can help speed up root cause analysis. Similarly, there are facilities for say, power grids or gas distribution companies to represent their assets on a map.

DARPA (Defense Advanced Research Projects Agency) has stated that it believes that the new generation of artificial intelligence will involve what it described as “contextual (machine) learning”. This is precisely the space within which TrendMiner is operating. In particular, it supports a self-service approach to analysis that does not require domain experts to have any knowledge of data science. This contextual strength, plus the fact that it integrates with other Software AG products such as WebMethods and Cumulocity, and not to forget its core capabilities, makes the product an obvious choice for shortlisting when it comes to process manufacturing. But therein lies the rub: there is a paucity of general-purpose analytics tools that work with time-series and we would like to see TrendMiner extended, not just to discrete manufacturing but to time-series analysis more generally, particularly in support of predictive and prescriptive maintenance.

The Bottom Line

“Self-service” is a term that is increasingly bandied about, quite often when it shouldn’t be. However, it is an expression that you can genuinely apply to TrendMiner and we find the approach taken by the company to be very intuitive. It is highly recommended.

Related Company

Connect with Us

Ready to Get Started

Learn how Bloor Research can support your organization’s journey toward a smarter, more secure future."

Connect with us Join Our Community